High Speed Glazed Tile Roll Forming Machine

Key Parameters

Material: Color steel coil, galvanized coil

Thickness of Material: 0.4-0.6 mm

The primary roll forming machine driving motor: 7.5KW

Line speed: 3–4 m/min (or 5-6m/min)

Description

One of China’s roof sheet roll forming machines leading manufacturers is Xiamen Beenew Machinery. Similarly, we are able to provide various roll forming equipment for various types of Glazed Tile Profile Sheets. Metal tiles are easier to handle than long-run corrugate sheets, lighter than concrete or clay tiles, and more resilient than asphalt shingles.

Benefits of using metal roofing tiles are:

1) Design of architecture;

2)Sturdiness;

3) Performance;

4)Sustainability

5)EXPENSIVE

Show us your design drawing if you have, so our engineer can offer some helpful suggestions.

Description of Forming Machine

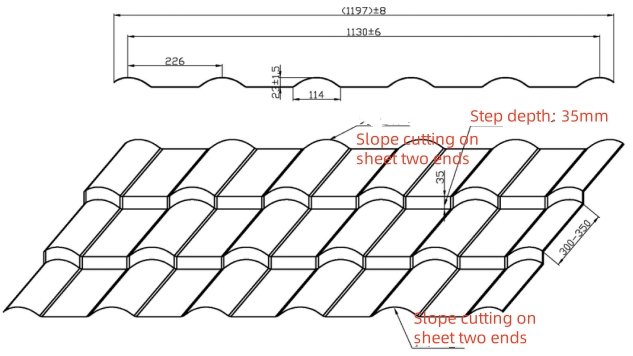

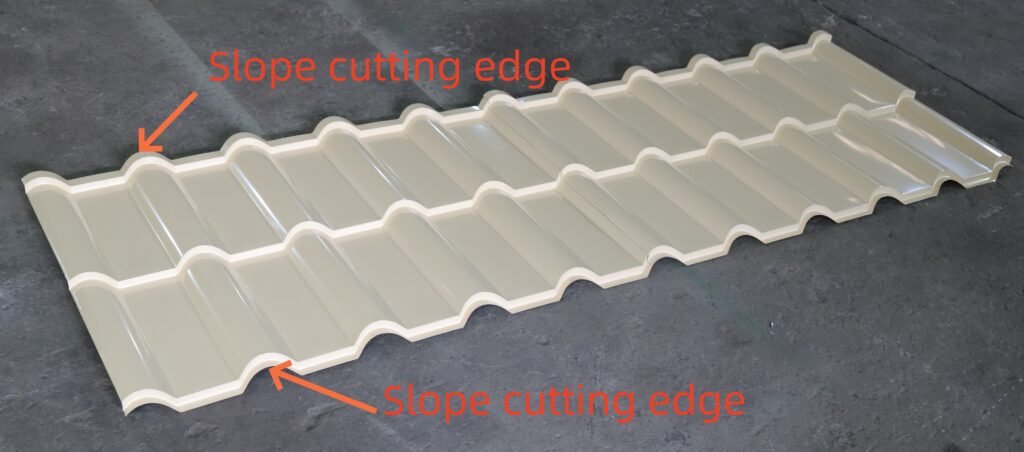

By automatic feeding, shaping, and cutting metal coils into precise shapes, the glazed tile roll forming machine produces step tiles with improved weather resistance, fireproofing, and lifespan over conventional materials.

This high speed glazed tile roll forming machine has combined hydraulic cutting systems, programmable logic controllers (PLC), and automatic decoiling mechanisms to guarantee perfect consistency, high-speed output, and little waste.

Key Parameters

Material: Color steel coil, galvanized coil

Thickness of Material: 0.4-0.6 mm

The primary roll forming machine driving motor: 7.5KW

Line speed: 3–4 m/min (or 5-6m/min)

Principal Elements

5tons manual de-coiler, manual pre-shearing with guide, roll forming system, hydraulic cutting device, control system, run out table.

Every technical parameter for each part

- Manual decoiler with a 5T loading capacity

I.D. of steel coil: φ480-φ530 mm; O.D. of steel coil: φ1300 mm; maximum coil width: 1219 mm

- The Roll Forming Machine

14 roller stations and roller groups

Roller material: 45# steel, heat-treated chrome coating, HRC58-62°

Diameter of roller shaft: Φ75mm

Shaft material: 45# steel that has been tempered and quenched

Transmission method: chain; machine frame body: H-beam; motor: 7.5KW Stress-Relieving, Welded

Wall panel and roller stand

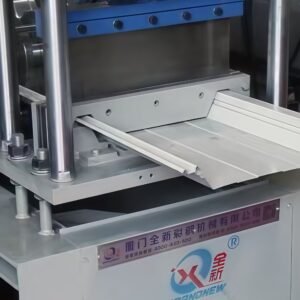

- Hydraulic cutting Unit

Making a cut Stop cutting with hydraulics

5.5kw hydraulic pump motor

Cutting die Cr12 with quenching procedure

- Cabinet for electricity control

Frequency inverter, DELTA brand PLC, View touch screen, Omron encoder and power supply is 380V/50HZ/3P (or customized).

By roll forming metal sheets into profiles that closely resemble wood, this glazed tile roll forming machine improves metal roofing designs. This technique combines the lightweight, fire-resistant, and metal weatherproof advantages well.

Glazed tile roll forming machines create metal roofs that are perfect for today’s needs. And we have improved the line speed well from 3-4m/min to 5-6m/min, we have our own skills on the type of metal roofing machines. Welcome to chat with us for high speed tile roof roll forming machines now!

Reviews

There are no reviews yet.