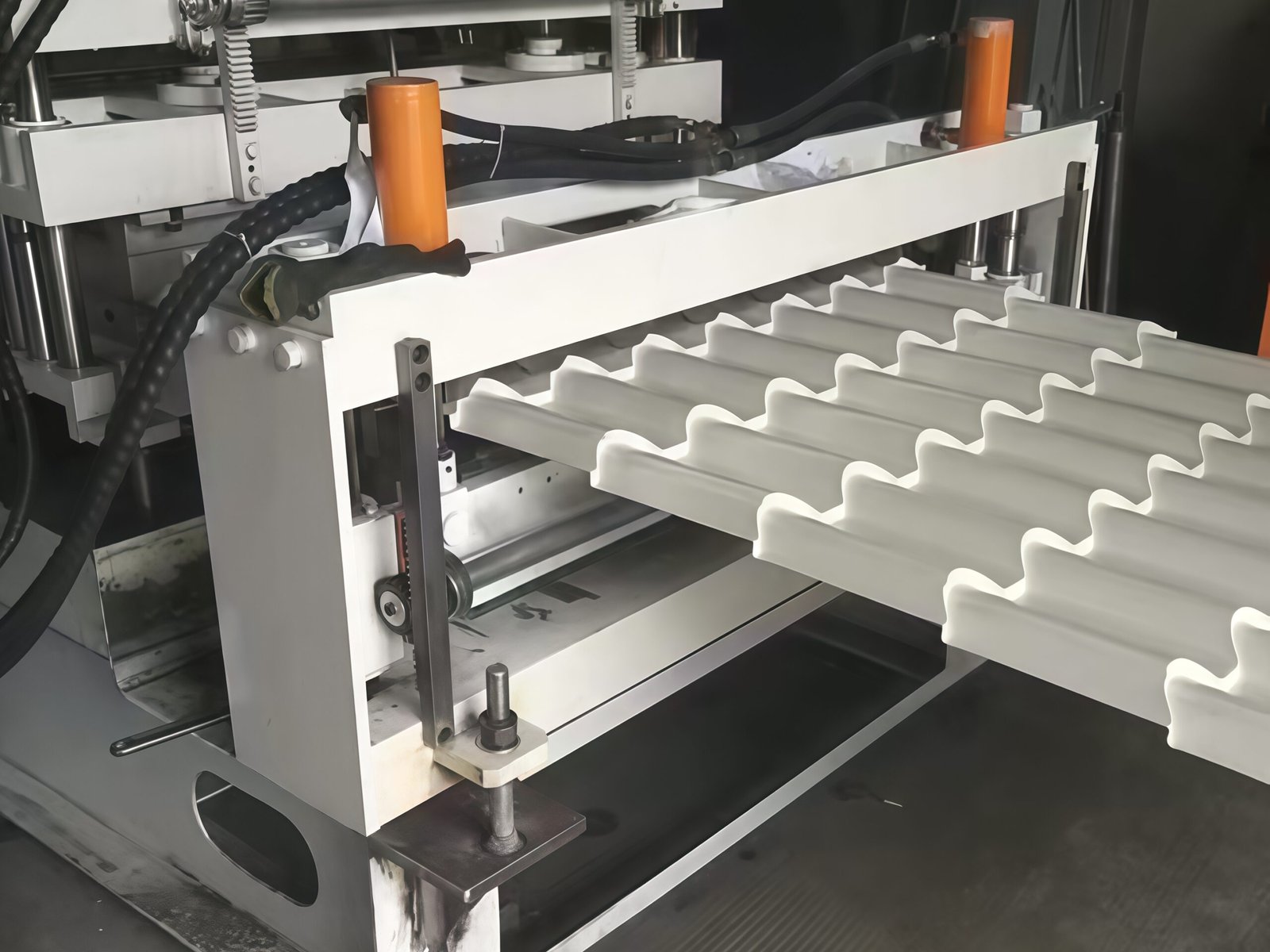

Fast Speed Step Tile Roll Forming Machine

Step tile roll forming machine is also known as a metal roof tile roll forming machine, a glazed tile roll forming machine, and so on.

Description

Fast Speed Step Tile Roll Forming Machine

One of the most often used roll forming machines is the steel step tile roll forming machine. It is also known as a metal roof tile roll forming machine, a glazed tile roll forming machine, and so on. Although the general shape of metal roof tile roll shaping is consistent throughout countries, there may be minor variations.

Processing of Step Tile Roll Forming Machines Source Material:

Steel Types: Galvanized Steel, Coated Steel, etc.

Steel Metal Thickness: 0.3 to 0.7 mm

Maximum Coil Weight: 12T;

Maximum Sheet Width: 1300 mm

The number of roll forming stations: 16

Step Tile Roll Forming Machine Line components

6Ton X 1250 Hydraulic Un–coiler With Coil Car

Hydraulic system to expand coil inner hole, Pump motor: 3.0KW

Coil Inner-diameter= 510±30mm. Coil Outer-diameter Max. 1300mm

Load Capacity: Max. 6 Tons, Coil Width Max. 1250mm

Link-connect expanding system

Retarding Motor to turn the coil. Motor:2.2KW

Up/Down stroke of Coil Car: Max. 250mm

Forward/backward stroke of Coil Car: Max. 2000mm

Separated electric controller, it is good for maintenance roll forming machine line

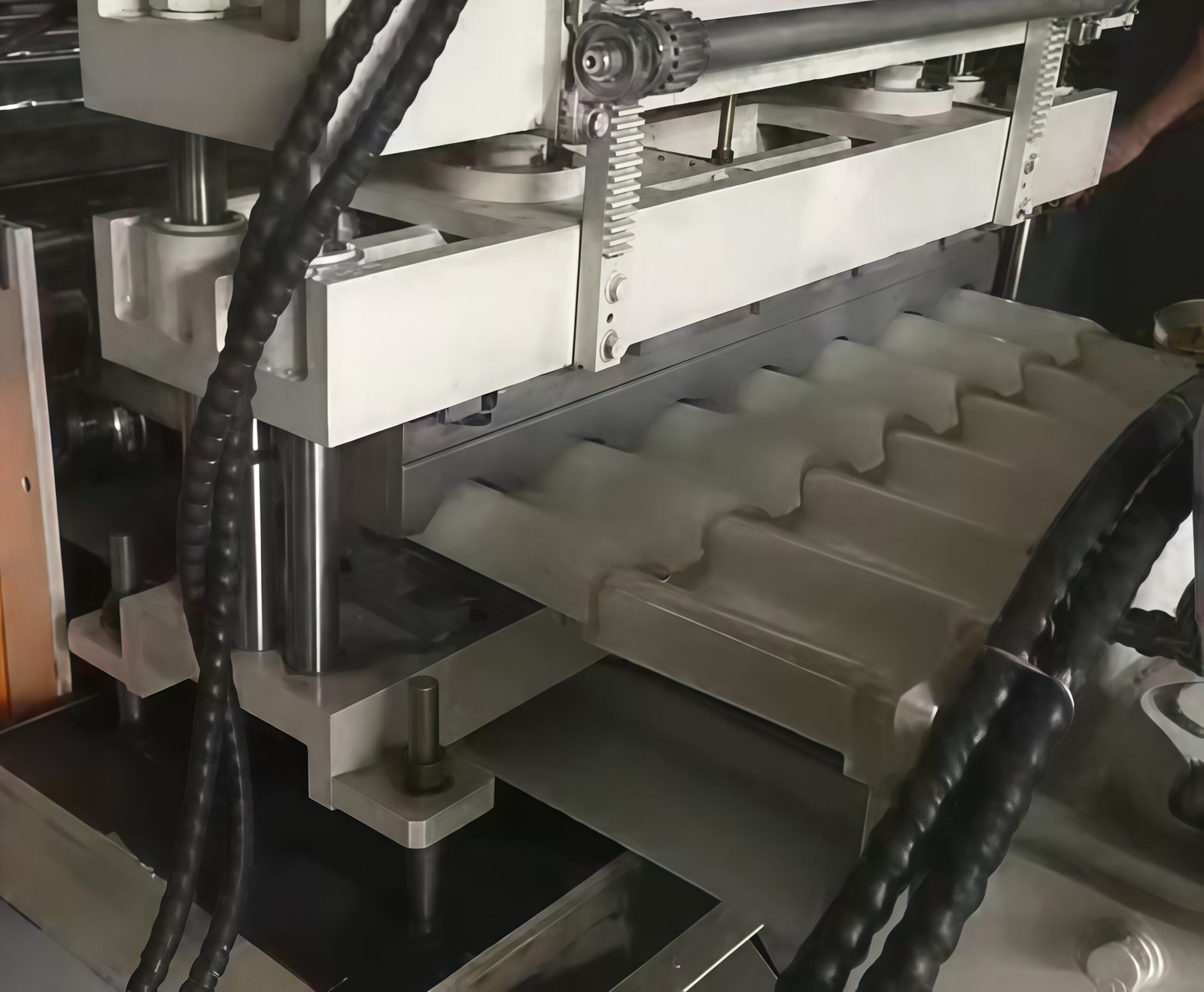

Cold Roll Forming Machine

With Manual pre-shearing, it is for cutting non-used material tails

Feeding section with guide;

Machine frame made from H400 beam, side wall thickness: 18mm

Step tile depth: 18mm

Gear/Sprocket driving; 16-step to form

All forming rollers are CNC lath, and made from 45# steel,hard Chrome Coated

Shafts Diameter=ф75mm, Precision Machined

Servo motor for increasing speed and precision

Servo motor power: 7.5 KW, Frequency speed control

Forming speed:Approx.4-6m/min

Hydraulic pressing /cutting device

Stop to press, pressing mold: three beam four columns

Post cut, two pieces of blade cutting, no slug cutting off

Pump motor =7.5KW; Cutting pressure=Max.10Mpa

With cooling system for hydraulic station

And all hydraulic valves are famous brand for ensuring working life

Cutting/pressing tool material: Cr12, Heat treatment

PLC Control System

Control length & quantity & cutting length automatically.

Combined with:PLC, inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control voltage 24V

So would like to choose a high quality and fast speed step tile roll forming machine? Try one time to improve your villa house roof output!

Adas –

Good quality machine