Standing Seam Metal Roof Machine

Main Parameters:

Coil Thickness:0.6-1.2mm

Coil Width:575/600mm

Effective Width:400/425mm

Forming Steps: Totally 13 steps to form

Description

Main Parameters:

Coil Thickness:0.6-1.2mm

Coil Width:575/600mm

Effective Width:400/425mm

Forming Steps: Totally 13 steps to form

Introduction:

The standing seam roof panel forming machine is a specialized device that shapes metal coils—like aluminum-magnesium-manganese alloy or galvanized steel—into profiled roof panels with integrated vertical seams automatically and continuously, right at the construction site.

It enables on-demand production of panels customized to project-specific measurements, minimizing overlapping during installation and cutting down on material waste.

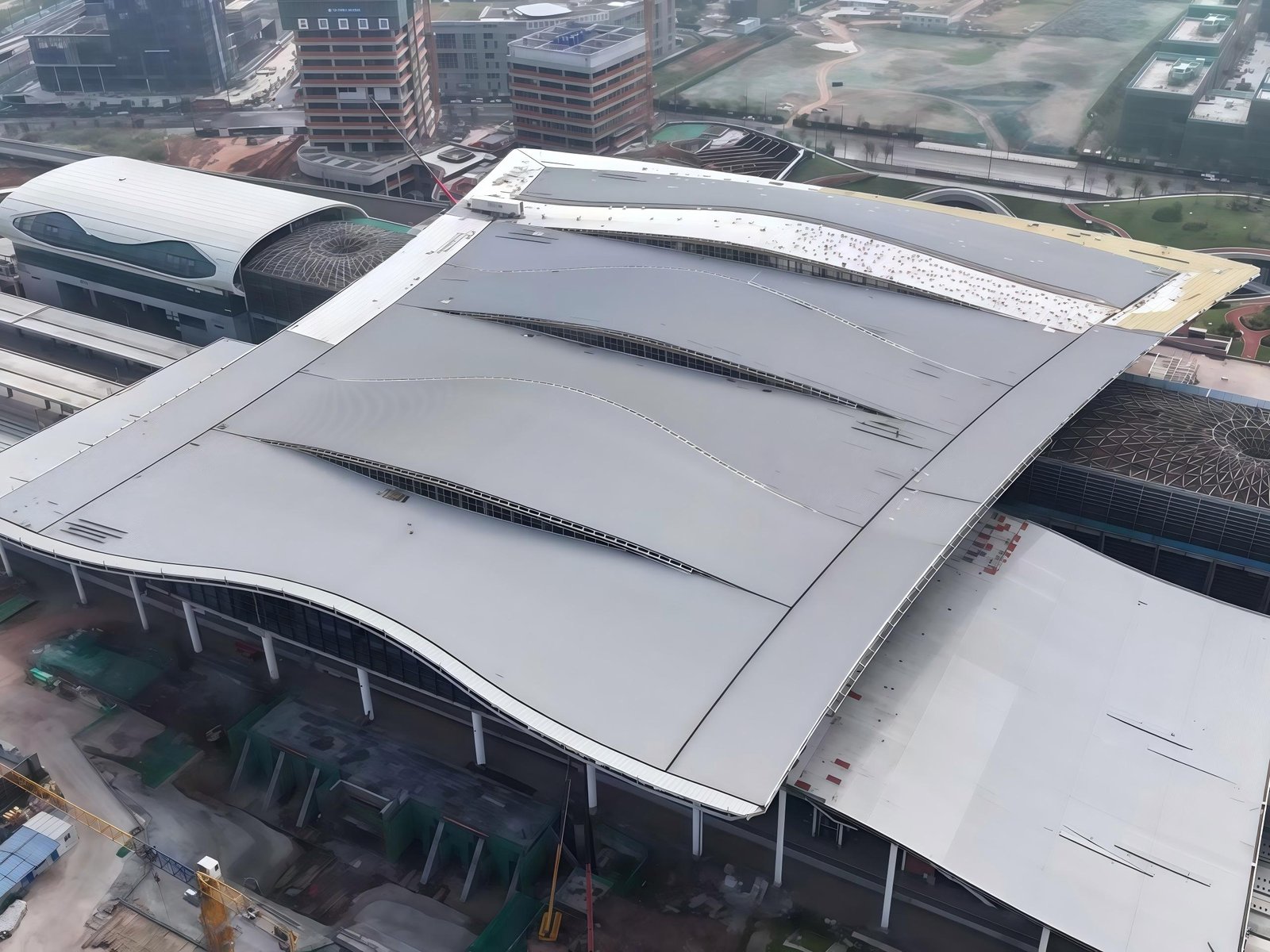

Effect Presentation:

The high-precision roll forming guarantees tight and accurate interlock between adjacent panel ribs, creating a structurally continuous and highly water-resistant roof surface.

Application:

Thanks to its superior weather resistance, wind performance, visual appeal, and adaptability to long-span designs, standing seam roofing is widely specified for large public and industrial construction projects. Typical applications include stadiums, airport terminals, convention centers, performance halls, logistics warehouses, and manufacturing facilities.

Reviews

There are no reviews yet.